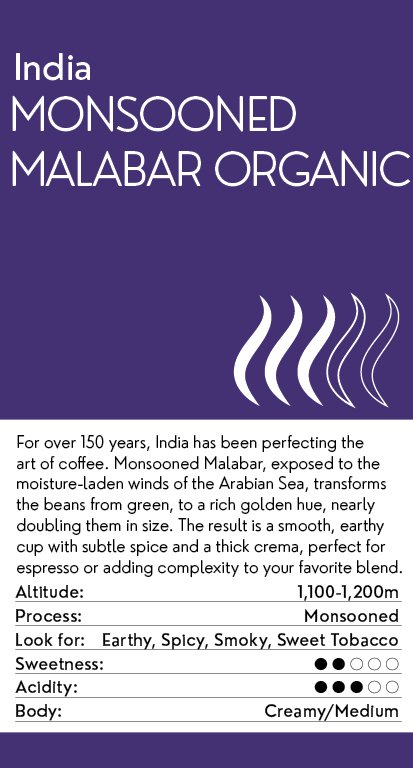

India Monsooned Malabar Organic

For over 150 years, India has been perfecting the art of coffee. Monsooned Malabar, exposed to the moisture-laden winds of the Arabian Sea, transforms the beans from green, to a rich golden hue, nearly doubling them in size. The result is a smooth, earthy cup with subtle spice and a thick crema, perfect for espresso or adding complexity to your favorite blend.

For over 150 years, India has been perfecting the art of coffee. Monsooned Malabar, exposed to the moisture-laden winds of the Arabian Sea, transforms the beans from green, to a rich golden hue, nearly doubling them in size. The result is a smooth, earthy cup with subtle spice and a thick crema, perfect for espresso or adding complexity to your favorite blend.

For over 150 years, India has been perfecting the art of coffee. Monsooned Malabar, exposed to the moisture-laden winds of the Arabian Sea, transforms the beans from green, to a rich golden hue, nearly doubling them in size. The result is a smooth, earthy cup with subtle spice and a thick crema, perfect for espresso or adding complexity to your favorite blend.

The Producer

While many people know India as a producer of fine teas, it has been growing and exporting exceptional coffees for more than 150 years. Today, India is the fifth-largest producer of Arabica coffee in the world, behind Brazil, Colombia, Mexico and Ethiopia.

“Monsooning”

The colour, shape, and size of these beans from India, as well as their aroma and taste, are the result of special post-harvest processing. Historically, coffee was shipped to Europe in wooden sailing vessels that took four to six months to sail around the Cape of Good Hope and up to their destinations.

The monsooning process consists of exposing natural coffee beans, in 4- to 6-inch-thickpiles, to moisture-laden monsoon winds in a well-ventilated brick or concrete-floored warehouse. This process is carried out on the West Coast of India, making use of the winds from the Arabian Sea during the southwest Monsoon months of June through September.

The processing begins with top-grade beans, Arabica cherry AB, that has already been processed by the dry method. To equalise moisture absorption, the beans are raked frequently, followed by bulking and re-bagging at regular intervals. During this 12- to 16-week process, the beans absorb moisture in stages, swelling to nearly twice their original size and developing colors ranging from pale gold to light brown. After several weeks, the coffee is re-bulked, graded again, bagged and moved to a drier region for longer-term storage.

The end result is a unique flavour that (like licorice, or cilantro) appeals to a group of ardent fans. It adds interesting notes to a blend and a rich crema to espresso.